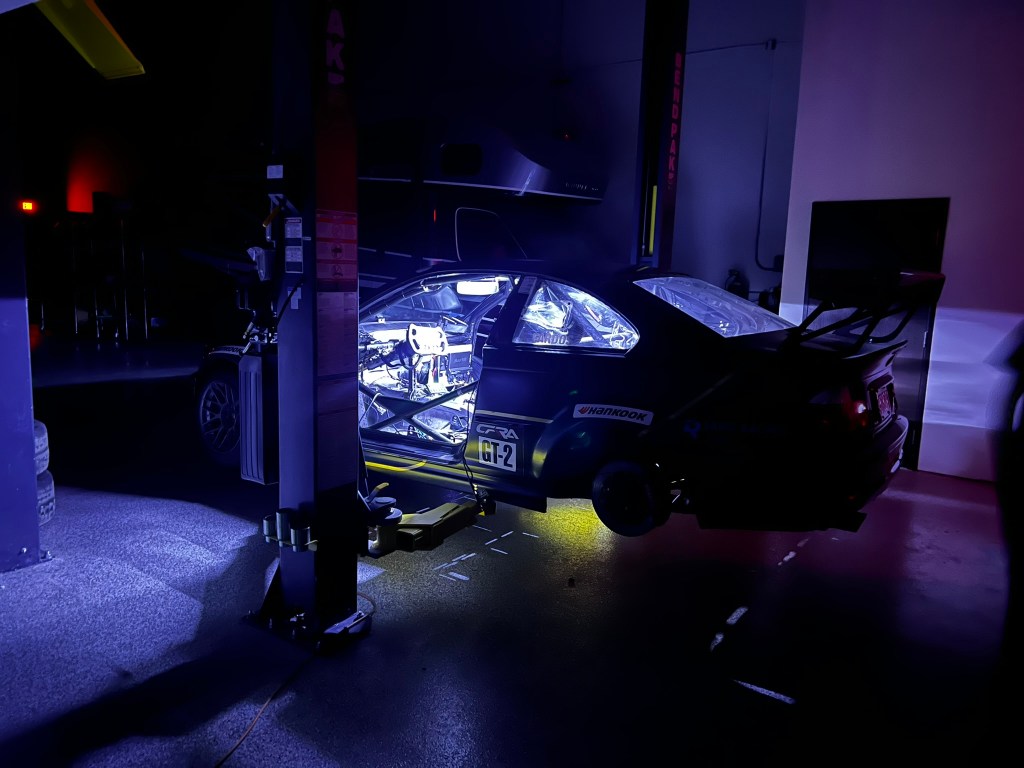

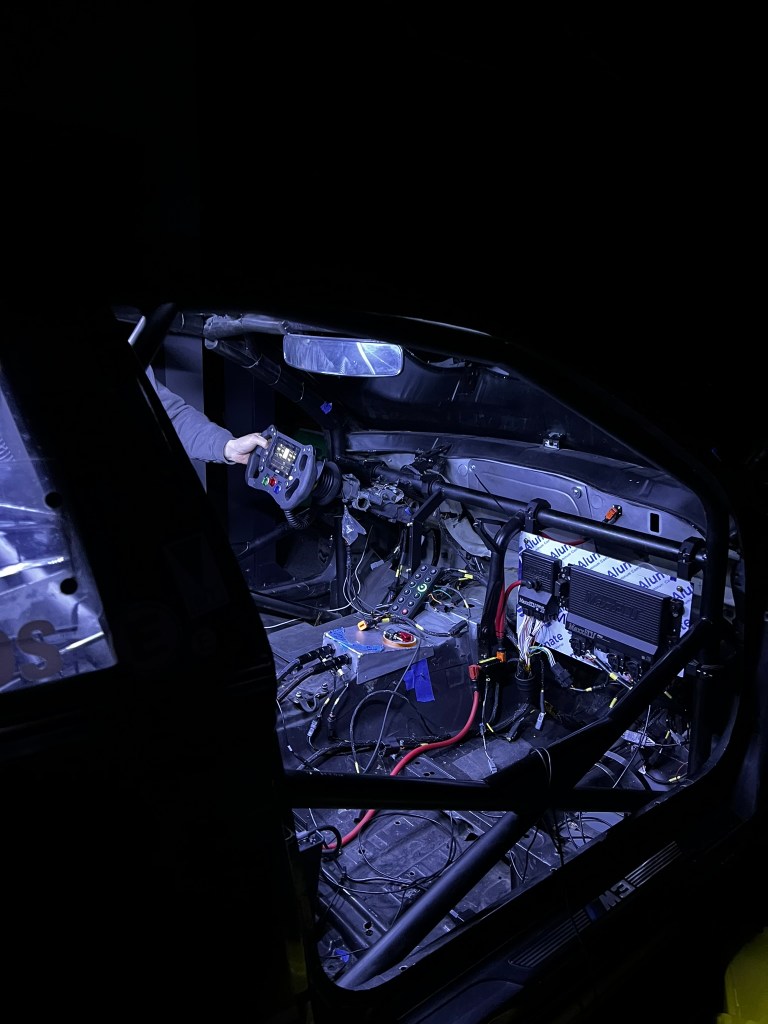

This project has been our most ambitious club racing endeavor to date. It involved extensive CAN integration and a significant amount of custom calibration, utilizing the full capabilities of all onboard devices. The car is an S54-powered E46 M3 equipped with a DCT transmission. The powertrain is managed by a Maxx ECU Pro, while the chassis electrical system is controlled by a Maxx ECU PDM. An AIM SW4 steering wheel, paired with a CAN keypad, serves as the primary control and display interface.

The vehicle was brought to us for the complete design and construction of the wiring system, as well as the programming and calibration of all onboard electronics.

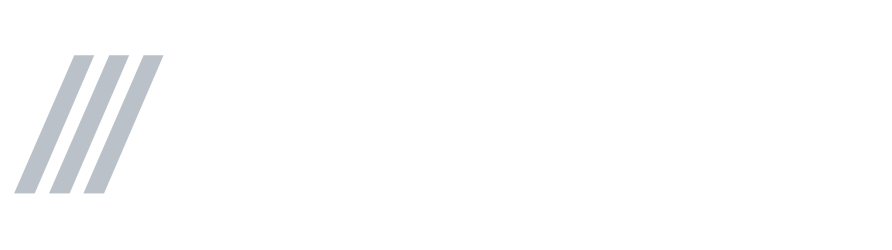

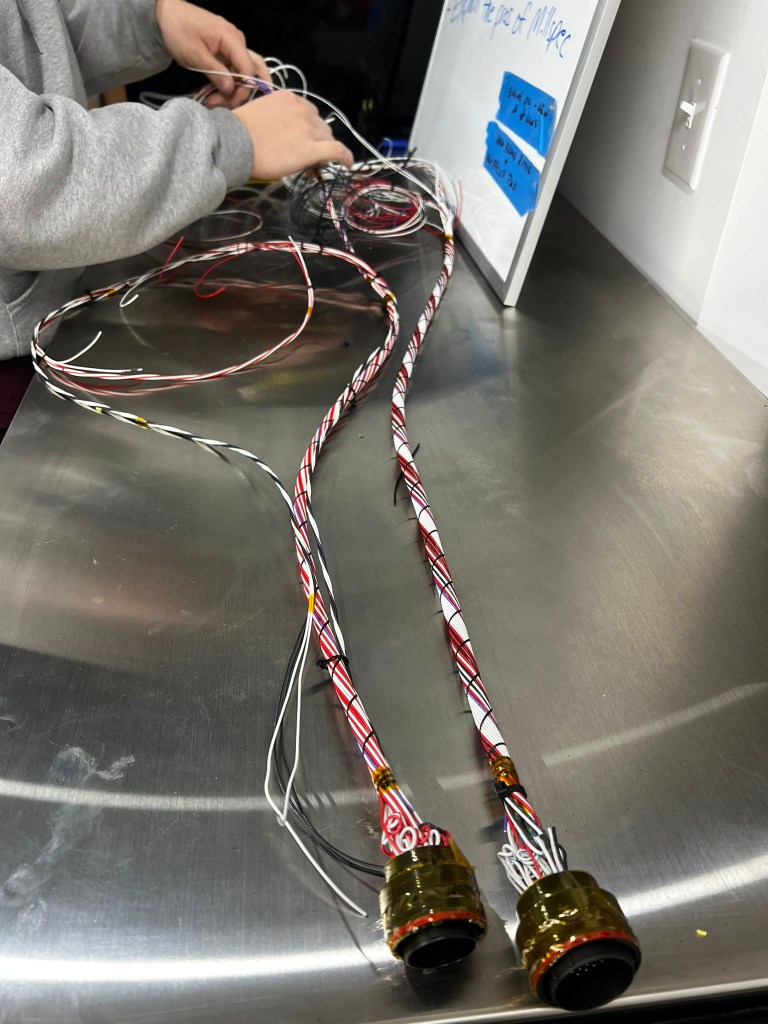

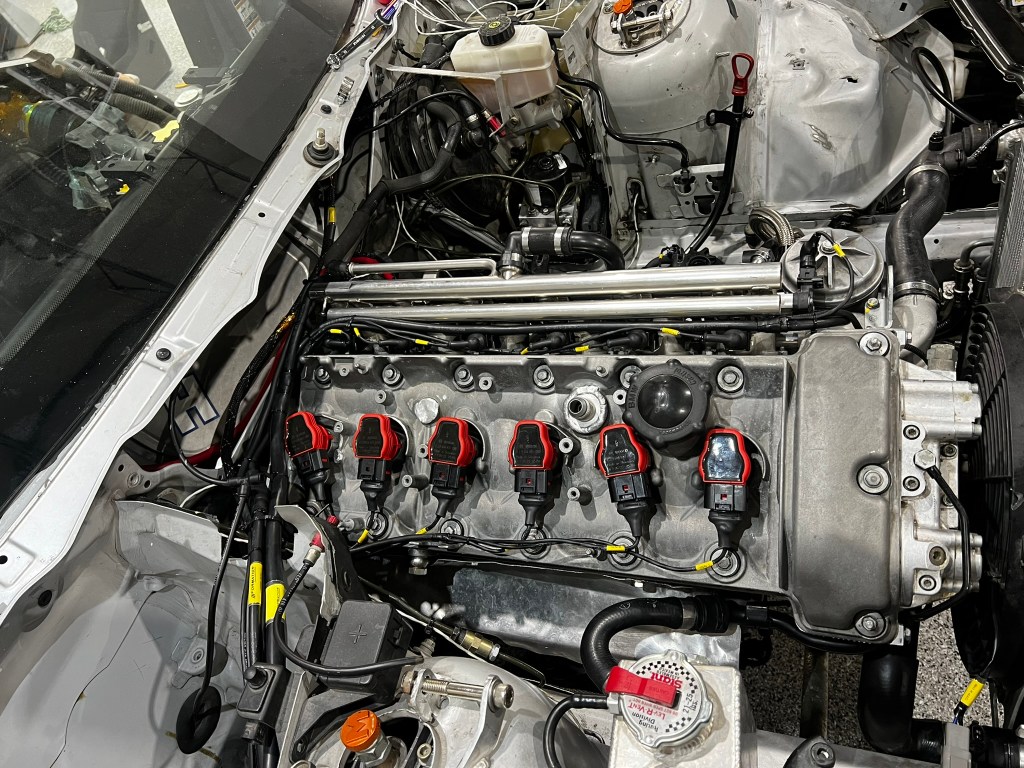

The engine harness is a fully Mil-Spec, concentrically twisted design—our premium wiring solution offered to customers seeking the highest standard for this engine platform. The planning, routing, and layout were meticulously executed to ensure all circuits operate as the factory originally intended.

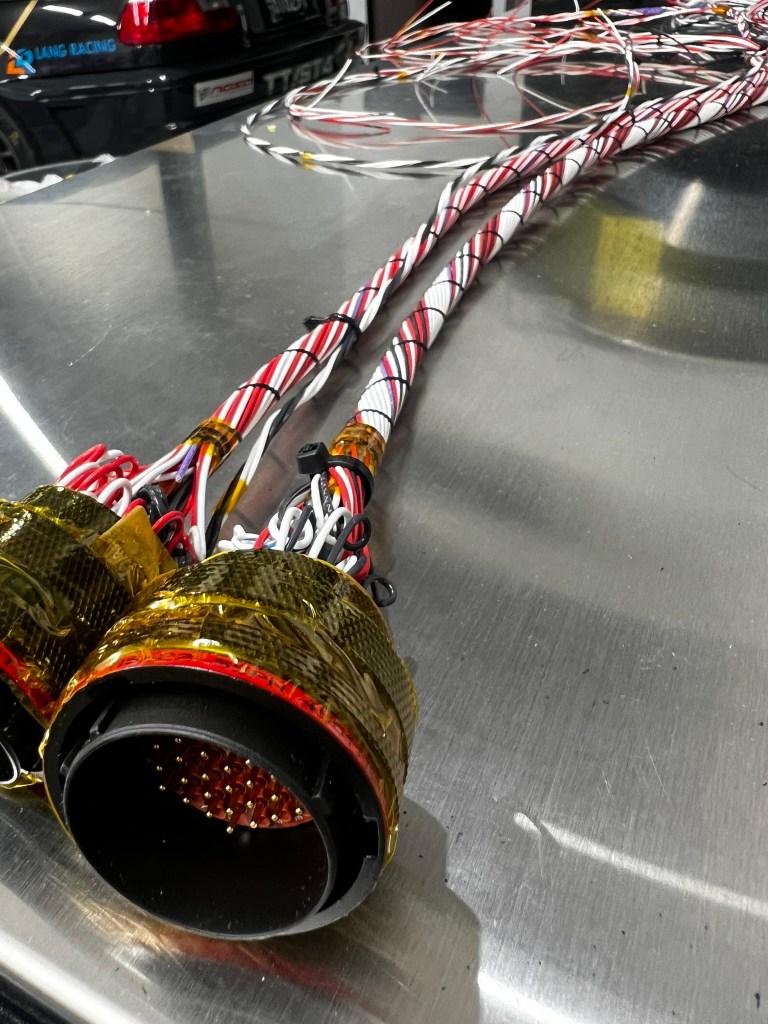

The chassis harness was constructed to a Club Spec level rather than Mil Spec, in order to manage project costs and allow for greater flexibility with future modifications or repairs. Despite the cost-conscious approach, the harness incorporates a wide range of sensors and actuators to support the vehicle’s advanced functionality.

The calibration of all onboard electronics was a success, with the integration of strategies that not only replicated factory ECU functionality but also expanded upon it with motorsport-grade features. By implementing IAC throttle control and optimizing VANOS mapping, the S54 engine performed exceptionally well. We can confidently say we reached the limits of what was possible using the vehicle’s existing hardware.

By incorporating CAN data from factory BMW systems such as the Mk60 ABS and the steering angle sensor we enabled a more complete suite of chassis data. This allowed for enhanced system monitoring and provided valuable insights for driver development.