We both started our journeys in the automotive world with one car — the BMW E30. This platform has been, and continues to be, a defining part of both our professional and personal paths. Over the years, several E30s have come and gone from our ownership, but we originally united over the idea of building a truly special one.

This car represents the culmination of the knowledge we’ve amassed over more than a decade working in the specialized worlds of classic BMW service, motorsport engineering, and electronics calibration.

It was built with the belief that highly modified project cars should still retain the cohesive spirit and character they had when they left the factory. We approached the build with an OEM engineering mindset — the car had to be balanced, capable across a wide range of use cases, and celebrate the joy of driving without sacrificing road-going comfort or amenities.

This is not a haphazardly conceived or unfinished project; every element has been carefully considered, and no corners were cut.

Engine

The vision for this car was to deliver linear, controllable power while capturing the magical essence of BMW Motorsport’s glory days — when high-revving, naturally aspirated engines with remarkable engineering DNA echoed through the Eifel Forest to victory on the Nürburgring Nordschleife and carried that same spirit onto the city streets of a Los Angeles commute.

The S54 engine embodies that heritage. It offers exhilarating performance without overwhelming the comparatively lightweight and classic E30 chassis design. It also avoids the extensive frontal airflow requirements and thermal-management challenges that higher-output, forced-induction engines demand.

This powerplant stands as a testament to BMW’s engineering prowess, incorporating technologies rarely seen in road-going production engines. Its camshaft control system operates at nearly 1,500 psi and allows for almost 100 degrees of valve overlap, while its individual throttle-body system uses a ballast intake tube and an oversized idle-control valve to manage the complex, non-linear airflow of the induction design.

The CSL-style carbon airbox further enhances the character of the engine but introduced significant packaging challenges. These were resolved through bespoke solutions — custom heater-core pipes and a complete redesign of the pedal housing assembly, relocating the brake booster and master cylinder approximately 1.5 inches to the left while maintaining perfect original pedal geometry. The airbox requires the addition of a MAP sensor for proper airflow characterization due to to loss of the all important MAF sensor.

The engine itself is a stock S54 from a donor car, fully serviced and refreshed prior to installation.

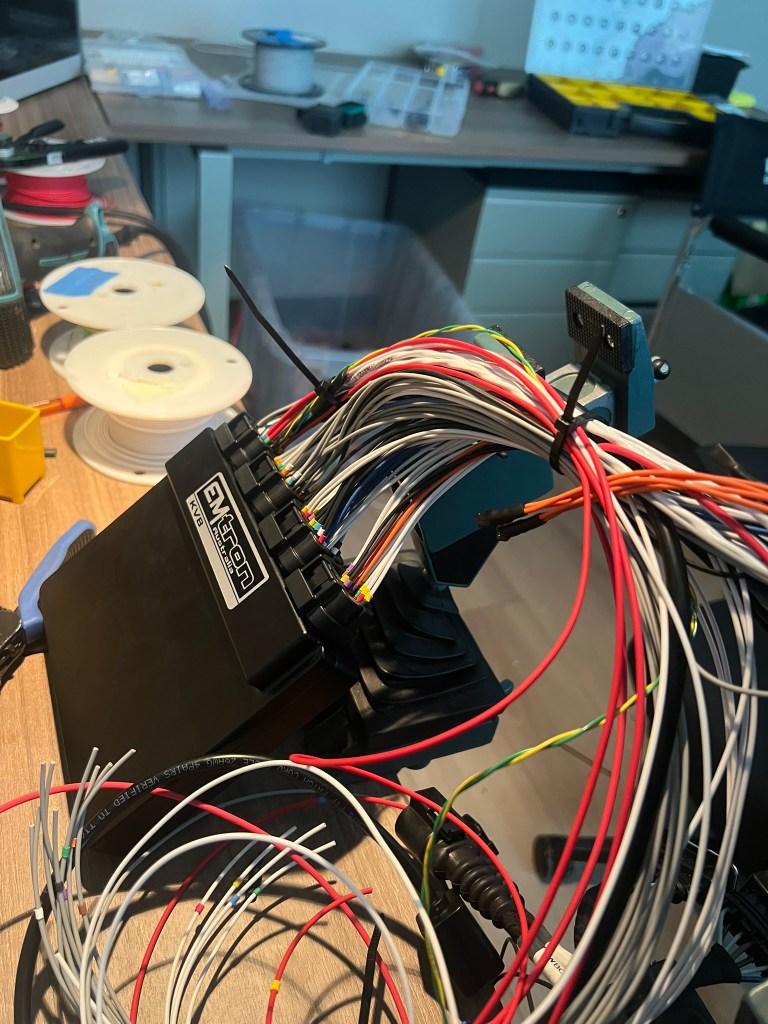

Engine Management

The S54 is an exceptional engine, and with that comes a host of unique engine-management challenges. The stock MSS54 DME — a superb ECU co-developed by BMW and Siemens — was engineered to deliver the refinement, drivability, and compliance expected of an OEM powertrain. However, when installed into a non-original chassis, the MSS54 introduces several integration and tuning limitations.

To achieve full control and flexibility, a standalone ECU becomes essential. In this case, the system must be sophisticated enough to manage the S54’s complex subsystems and maintain OEM-level drivability and precision.

We selected the Emtron KV8, whose advanced air-mass modeling and torque-based control architecture provide an ideal foundation for managing the engine’s unique requirements. Its ability to accurately govern the idle-air system, manifold pressure sensor, and unconventional drive-by-wire setup allows for seamless and responsive engine behavior.

A completely custom wiring harness was made utilizing all of the original engine harness plastic covers and holders in order to achieve a nearly indistinguishable from stock solution. This wiring harness was made using materials the met or exceeded OEM standards and allowed for the cleanest and most functional approach to engine and chassis integration, along with the addition of sensors not found standard on the E46 M3.

The calibration process was far from conventional. It demanded an in-depth understanding of custom control strategies and bespoke software solutions to create a precise air-mass model. Steady-state dyno tuning was conducted to open loop calibrate the air-modeling (TMF), volumetric-efficiency, ignition timing, and intake and exhaust VANOS tables — ensuring maximum output, efficiency, and consistency across all operating conditions. An accurate torque model has been produced for the engine and it has given us the ability to implement OEM standard precision control over many subsystems including cruise control, idle, traction control and pedal control. There has been over 100 hours put into the calibration of this engine management system between the on the dyno and qualitative drive ability nit picking . This has allowed us to achieve a better result than that of the factory Siemens DME which was engineered and calibrated at an extremely high OEM level.

Driveline:

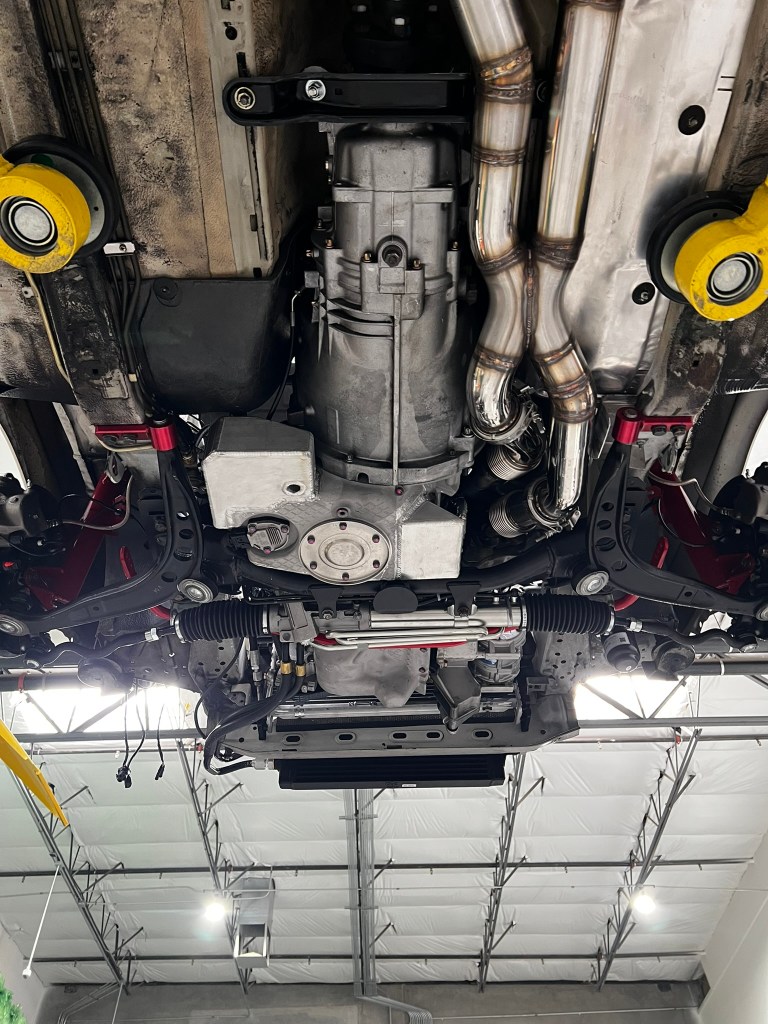

An E36 M3 ZF320 gearbox was selected for its lightweight construction, strength, ideal gearing, and excellent shift quality. The clutch and dual-mass flywheel were chosen to minimize idle chatter while still reducing overall assembly mass compared to the factory components. The entire clutch assembly was custom-manufactured in Germany specifically for this application.

A new E36 M3 driveshaft was fitted and paired with a factory BMW 2.93 limited-slip differential. This final-drive ratio represents a 7% increase over the E46 M3’s factory gearing, but due to the significantly lower mass of the E30 chassis, it delivers improved off-the-line performance while maintaining a comfortable and efficient highway cruising behavior — approximately 75 mph at 3,200 rpm.

After extensive evaluation of nearly all available aftermarket and body-mounted shifter solutions, we ultimately designed a custom system utilizing a factory BMW shifter, a Z3 selector, and an OEM ZHP weighted shift knob. This combination provides the most precise and tactile shifting experience while preserving factory ergonomics and mechanical integrity

Suspension and Brakes

Much of the suspension has been replaced for both performance and integration. The front setup uses E36 M3 (1996–1999) front knuckles and brakes, combined with Ground Control coilovers featuring Koni single-adjustable dampers and Eibach springs. This allows for proper caster settings and adjustability in ride height, and camber.

Currently the rear of the car is equipped with a “serrated teeth” adjustable rear subframe in order to allow for adjustability to both the rear toe and camber settings and allow us to maximize the rear tires mechanical grip.

The rear suspension employs an SRS Concepts E30 five-lug conversion kit, incorporating Z4 rear hubs and E46 328i calipers and rotors.

These brake dimensions very nearly match the BMW specified rotor size in the rear and match the rotor sizing in the front of the similar yet slightly heavier Z3M equipped with the same engine.

A Porsche 944 brake booster and an E32 master cylinder were selected to successfully clear the carbon air box and work with the larger calipers to give a proper OEM brake feeling.

An Eibach adjustable front sway bar was also installed and relocated to sit ahead of the subframe, mirroring the geometry of the later E36 and E46 chassis. This modification required the fabrication and welding of custom sway bar mounts to the E30’s frame rails to ensure proper fitment and rigidity. The brackets were seam sealed in a factory technique to achieve a result that looks and functions to an OEM standard.

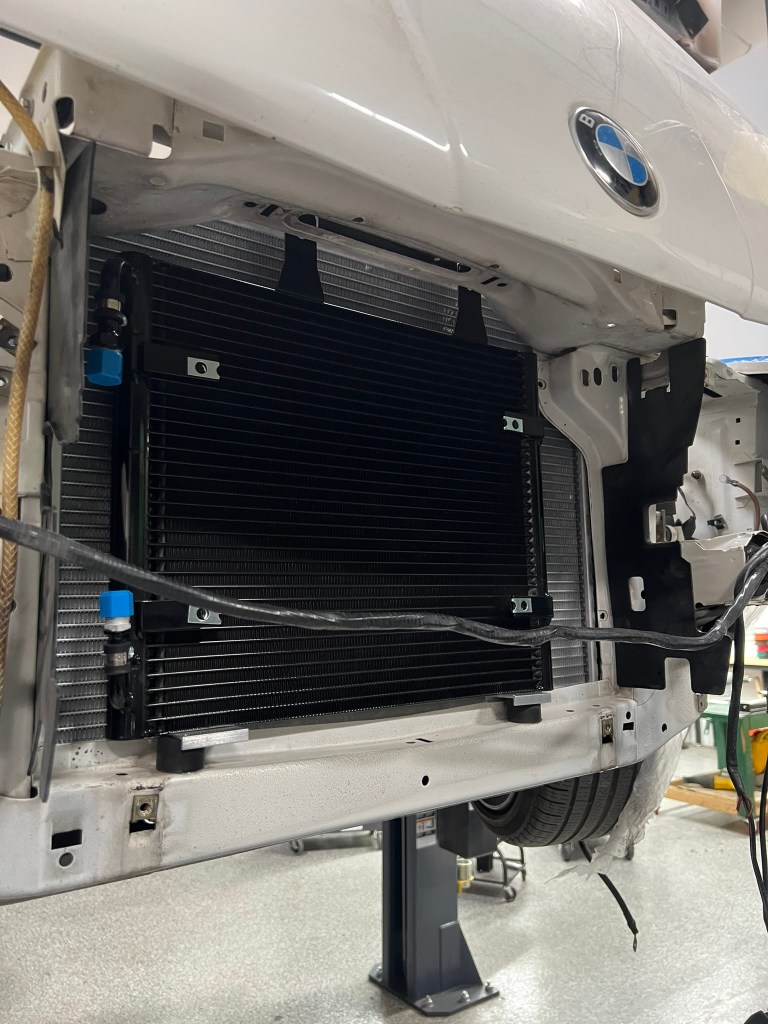

Cooling

We are using a factory Z3M radiator originally engineered to keep an S54 cool and an E30 M3 DTM specification oil cooler from CSF. The car runs nearly perfect 90C coolant and oil temperature even with spirited driving.

A/C

The car is equipped with a complete E30 24 valve A/C Solutions complete kit. We were able to achieve nearly 40F A/C on a 90F day.

Oiling System

One of our favorite parts of the S54 was retained, its well designed motorsport grade dual pickup oiling system. We were able to maintain this thanks to a extensively and professionally modified S54 oil pan and front E30 subframe. The OEM E46 M3 CSL oil dipstick was also utilized. All factory style hardlines and plumbing solutions were modified in a manner that allowed for their usage rather than any motorsport or aftermarket style AN fittings or hoses.

Chassis

The E30 chassis began as a clean, well-preserved California donor car with all original paint and body panels. It has never sustained any significant crash damage, with the factory solder joints on the front fenders confirming they have never been removed. The original interior has been retained and remains in excellent condition.

A key goal for the project was to start with a chassis that required little to no repainting or re-undercoating. The car was fully disassembled mechanically and dry-ice blasted from the engine bay to the underside at the rear spare tire well. The original engine bay paint was preserved, with only minor touch-ups performed by airbrush where necessary.

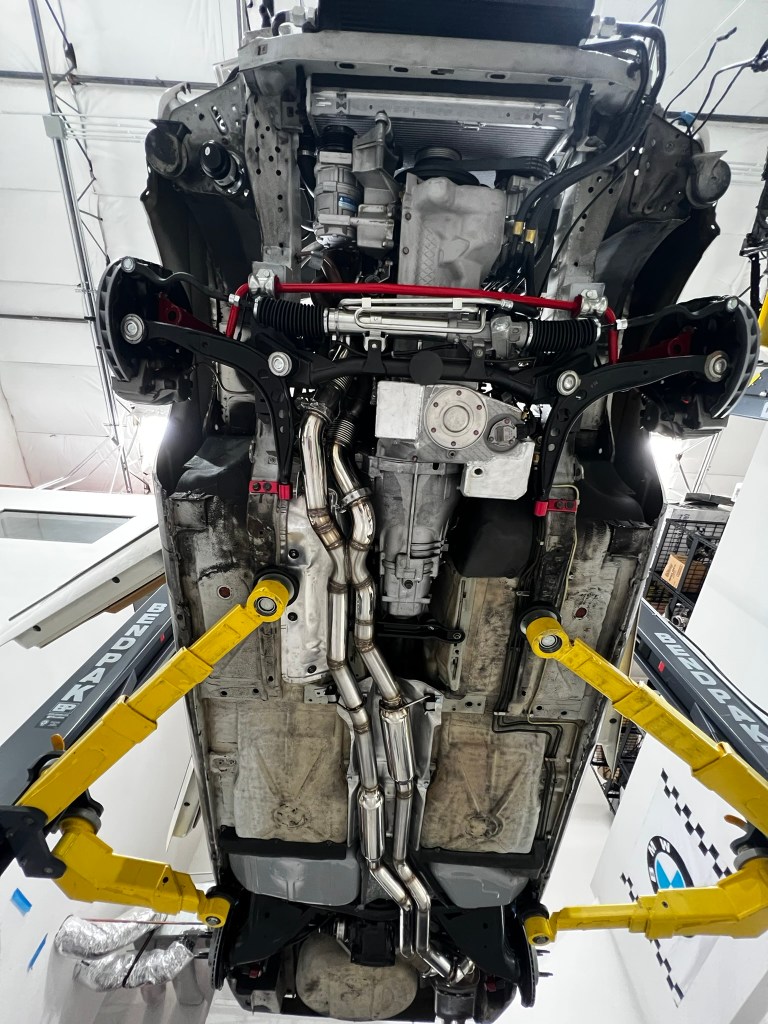

Exhaust

The exhaust system is a fully custom, TIG-welded 2.5-inch dual setup featuring two X-pipes — one positioned just past the front control arm lollipops and another integrated into the rear back box muffler. This configuration eliminates the characteristic rasp often associated with S54 engines, producing a smoother and more refined exhaust note.

The entire system is significantly lighter than an OEM equivalent and is tucked closer to the chassis, providing better ground clearance than even the factory M20 E30 exhaust layout. A key objective was to retain all of the original E30 exhaust heat shielding, which was successfully achieved. The factory BMW exhaust manifolds were used and modified to suit the application.

Chassis Integration and Functionality

Extensive effort was made to retain and preserve the original factory systems, including full functionality of the ABS, on-board computer, HVAC controls, and cruise control. The factory instrument cluster remains fully operational, supplemented by a Gauge.S CAN display integrated directly into the cluster. This addition provides access to dozens of ECU data channels via the CAN bus without compromising the original appearance or functionality.

Conclusion

The guiding principle for this build was straightforward: to imagine how BMW themselves would have executed an E30 powered by the S54, and to realize it as faithfully as possible. Our goal throughout was to construct the car to a standard that could pass a German TÜV modified-vehicle certification — with every component, from plumbing to chassis systems, completed to OEM quality.

The result is a car capable of excelling in any environment: reliable and consistent on a racetrack, fully competitive with modern performance vehicles, rewarding and engaging on a windows-down canyon drive, yet refined and comfortable enough for highway cruising or daily use.